-

Screw air compressor

Features 1Save the loss during unloading. When the gas volume of the fixed-frequency screw machine fluctuates, the motor will consume 45% of electricity when it is unloaded; the permanent-magnet inverter air compressor is not unloaded, and there is no waste. 2 to save the loss of pressure difference. In order to avoid the frequent start of the impact on the unit and the power grid, the fixed-frequency screw machine sets the 1-2BAR differential pressure; the variable-frequency screw air compressor can start and stop indefinitely, only one pressure point. Each time the pressure difference is 0.14 BAR, the system energy saving is 5~7%. 3 Save energy consumption at startup. The starting current of the fixed-frequency screw air compressor is 3-6 times of the rated current, and the frequent start-up greatly consumes electricity; the permanent-magnet inverter air compressor starts with a soft start, and the maximum current does not exceed the rated current.

-

Button heading machine

The auto bar moving machine matched with cutter and heading machine together,achieve to auto cutting,heading and moving bar away way .NC controller,mote adopts VFD,accurate speed,stably work,handle and Automatic way change any time,it can work in any where,easy installation,energy-efficient,after sale service with commercial cost.

-

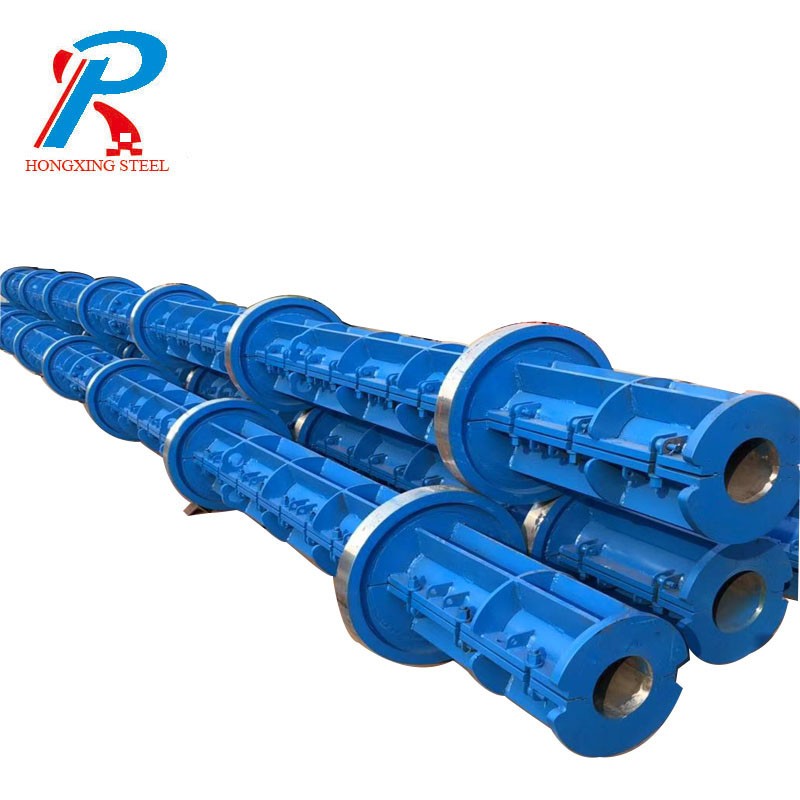

Tension jack machine

Tension machine is a kind of feedthrough pre-tensioing jack with a tension rod in the center, having 4 types of tensioning strength, namely: 1000 KN, 2000 KN, 3000 KN, 4000 KN. As the end of the tension rod is connected to the anchor with thread, it can be applied to various forged anchors, chilled iron anchor used for stayed-cable bridge and other similar anchors, as well as pre-tension pulling for pipes. In accordance with actual requirement, the support of two heavy-weight jacks can be replaced with a baseplate and rolling hinged bearing provided by the manufacturer, to be used as a vertical jack, or for horizontal pushing during installation. The customer can also demand a change in thread specifications for the connection of the anchor to enlarge the scope of application.

-

Diesel forklift truck

1.Equipped with Chinese powerful and reliable engines with excellent environmental performance; 2.Equipped with OPS or ORS seat and brake switch to prevent incorrect operation and secure the driver and the forklift from all sides. 3.install optional three-way catalytic device to lower the harmful emission beside of low emission engines; Adopt soundproof cotton to ease noise and high exhaust system as option to reduce dust.

-

Radial extrusion cement pipe machine

Vertical radial extrusion pipe manufacturing technology as a new type of pipe manufacturing technology has the greatest advantage of using dry and hard concrete, vertical production can be immediately demoulded.Instantaneous extrusion molding, each tubeonly 2 to 4 minutes, high production efficiency. The radial extrusion pipe-making machine issuitable for producing small and medium-sized concrete drainage pipes. Its diameter range is300mm-1200mm. Its standard length is 2-3m. It can also produce reinforced concrete cement pipes with flexible joints and pipe jacking without reinforced concrete cement pipes.

-

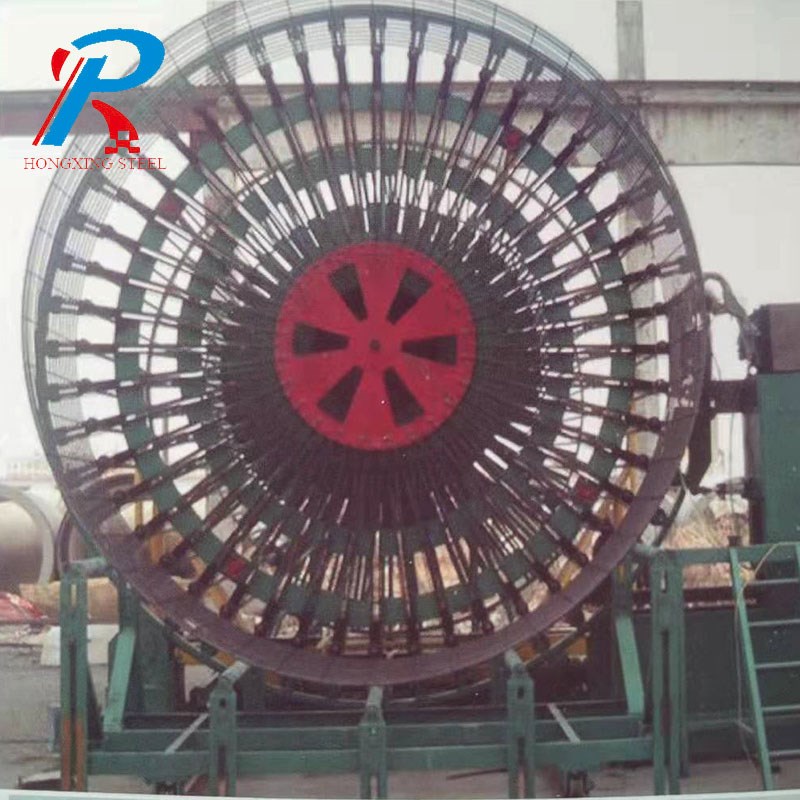

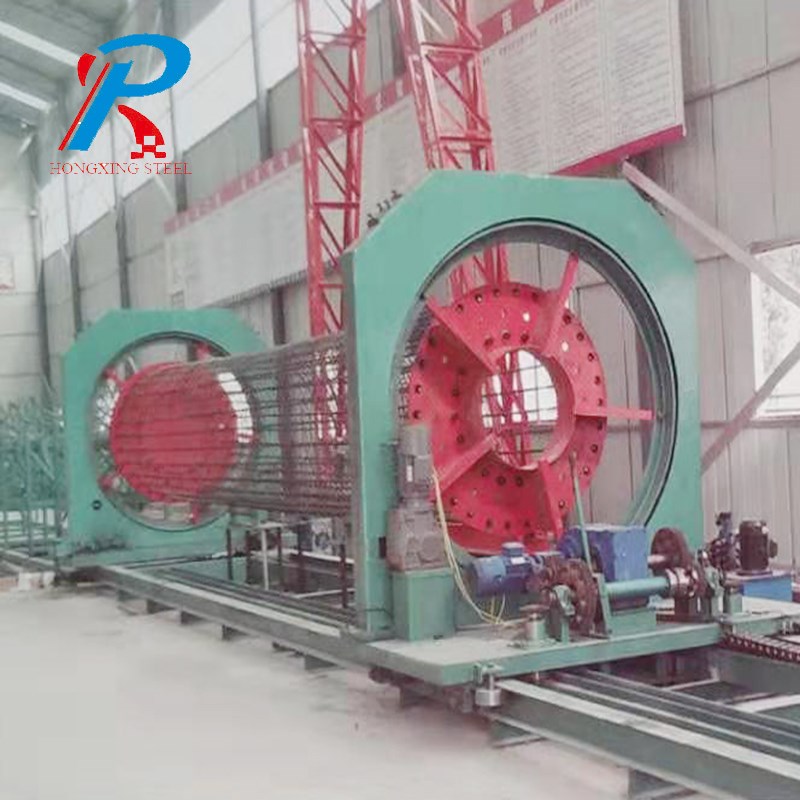

Automatic Rolling steel cage welding machine

Roll welding machine is widely used in cast-in-place pile construction in large bridges, high-speed railway construction and other fields. Wire Cage welding machine is one of the most necessary equipment to produce reinforced concrete pipes. There is pushing style, another is the Pulling. Our company pipe cage welding machine is fully automatic operation, the whole production process only needs one person operation. Roll welding machine makes up of four systems: The Main rotary plate; Pushing wire Plate; Diameter changing structure; and Cooper welder, they are working, driven by the separate motor. The Variable Frequency speed control system regulated to make the spiral pitch, the angle of ball joint.

-

Making steel mould for PHC Pile Moulds

According to Concrete pile strength , there are PHC piles, and PC piles, According to different wall thickness, there are PC piles and PTC piles. Spun pile production line is used to produce High strength Cocrete piles. The popular specification of PHC piles are3 00mm ,400mm, 500mm, 600mm, 800mm and 1000mm, the length can be 7-15 meters, or we can design the mould according to your request. Main Features 1. We keep absorbing advantages of similar advanced products all over the world to keep our products alway going first . 2. The structure of this mould is novel, they are made in sections, and couple with bolts. 3. This spun pile mould is easy to transport and quick to assemble. Positioning is accurate. 4. It has good overall rigidity and smooth operation.

-

Steel PC Strand Wire

Steel PC Strand Wire Applied to High-strength and stress tubular pile, pole,elevated bridge pier.ect Steel Grade:77B/82B Wire Gauge:1-50MM Standard:AISI, ASTM, BS, DIN, GB, JIS Model Number: 1x7 Prestressed steel bar is the compressive stress exerted on concrete members by pre-tensioning method or post-tensioning method before the use of structural members. In reinforced concrete structures, members will crack when they are tensioned. Although it does not affect safety, it does not feel good. In this method, the steel bar is first tensioned and then poured into concrete. When the strength reaches the requirement, the steel bar will be loosened, and the steel bar will shrink. The method of pre-tensioning and post-tensioning is to pour the reserved holes in the concrete, then add the tensioned steel bar after forming, and then anchor the two ends of the component with instruments.

-

Batching of cement machine

Automatic batching machine with frequency control of motor speed system,material door switch is controlled by a separate hydraulic unit,hopper with electric hoist,equipped with vibration device for meterial.according to user requirements,make theleft and right symmetrical configuation operation. For the consistence feeding of concrete into mold,feeding machine is the solution.The feeding concrete is done by having mold sits on trolley.The trolley moves inward to insert the concrete injection pipe into the center of the mold.As the trolley moves outward,predetermined volume of concrete is displaced into the mold.The speed of trolley and the volume of the concrete are electrically programmed to ensure high consistency of concrete volume throughout the production process.This will eliminate wastage of concrete

-

Electric Forklift for construction

1.Equipped with Chinese powerful and reliable engines with excellent environmental performance; 2.Equipped with OPS or ORS seat and brake switch to prevent incorrect operation and secure the driver and the forklift from all sides. 3.install optional three-way catalytic device to lower the harmful emission beside of low emission engines; Adopt soundproof cotton to ease noise and high exhaust system as option to reduce dust.

-

Rolling welder/steel cage welding machine

The steel cage welding on the basis of the development of nen non-prestressed steel cage processing equipment ,absorbing the advantages of similar equipment at present, the use of CNC technology, in addition to the processing of variable diameter bar, can also process the same diameter bar. Compared with the traditional steel bar forming method, the equipment has a high degree of automation, welding, diameter changing and forming are all completed automatically by the equipment and the processing and formingspeed is fast.

- Home >

- Products

Products

Get the latest price? We'll respond as soon as possible(within 12 hours)