Automatic Rolling steel cage welding machine

Brand :HONG XING

Product origin :Hebei, CHINA

Delivery time :15-30 days after receipt of deposit or L/C

Supply capacity :10 sets per mouth

Roll welding machine

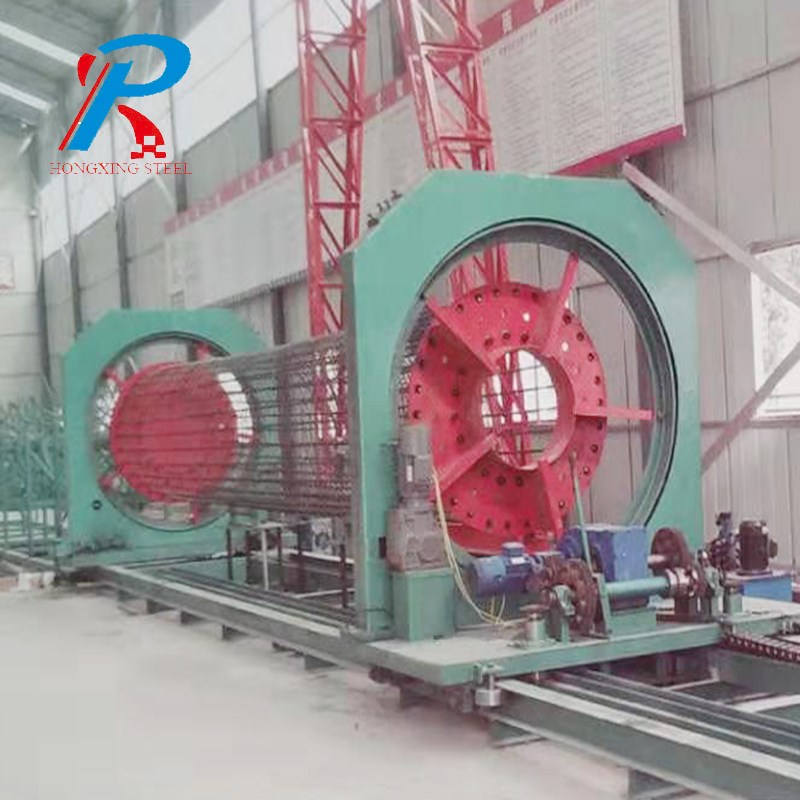

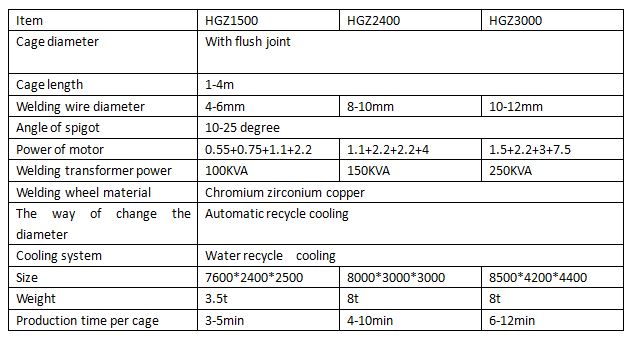

is widely used in cast-in-place pile construction in large bridges, high-speed railway construction and other fields. Wire Cage welding machine is one of the most necessary equipment to produce reinforced concrete pipes. There is pushing style, another is the Pulling.

Our company pipe cage welding machine is fully automatic operation, the whole production process only needs one person operation.

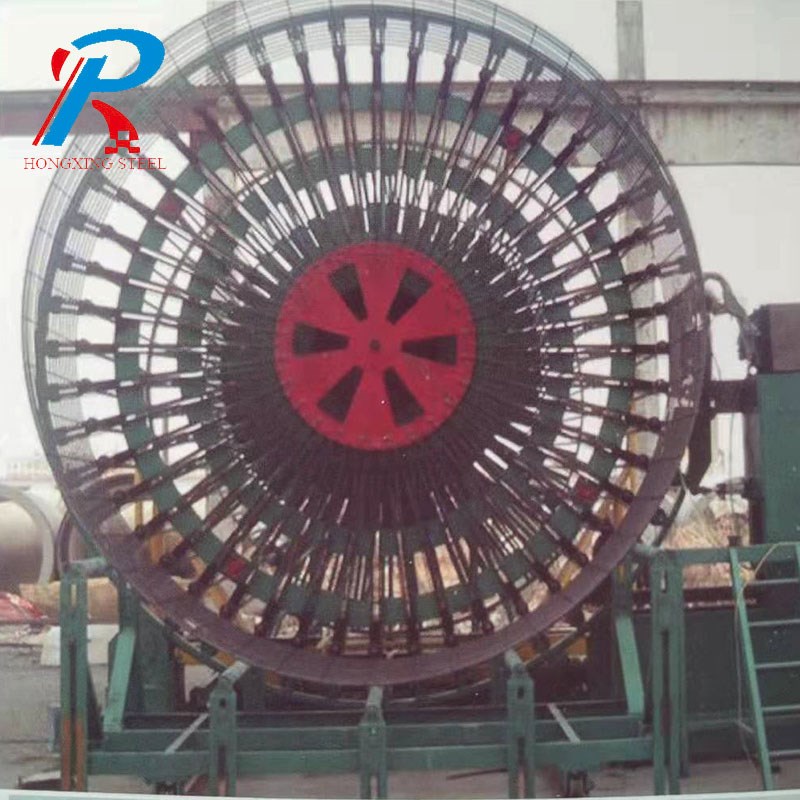

Roll welding machine makes up of four systems: The Main rotary plate; Pushing wire Plate; Diameter changing structure; and Cooper welder, they are working, driven by the separate motor.

The Variable Frequency speed control system regulated to make the spiral pitch, the angle of ball joint.

Product description

Voltage:380V

Current:20A

Rated Capacity:5KW

Rated Duty Cycle:60%-90%

Weight:4.5T

Usage:Rolling welding machine

Certification:ISO9000

After-sales Service Provided:Field maintenance and repair service, Online support

Warranty:1 Year

Product name:Welding Manipulator

Packaging and shipping

Lead Time:15 day(s) after payment received

Package Type:nude packing with container and truck .

Peyments:L/C T/T

Port: TianJin

Advantages and features

High degree of automation of equipment and high speed of processing and shaping. With ordinary peopleComparing with the traditional manual manufacturing, the method of forming is 3 to 4 times.

2. Processing quality is stable and reliable: because of mechanized operation,The spacing between the main rib and the winding rib is uniform and the precision is high.In this way, the disc bars are closely wound with the main bars; first, the inner stirrups are formed, and then the reinforcing cages are added.The same diameter ensures the concentricity of the reinforcing cage. The product quality fully meets the standard requirements. Supervisors basically exempt steel cages from inspection in mechanized processing

3. The processing cost is greatly reduced. When the same task is completed, the mechanical systemManpower can be saved by 3/4.

4. The fatigue strength of workers is greatly reduced. Because of mechanized operation, workersAs a supplementary role, the image of construction has been greatly improved.

5. The stirrups need not be lapped. Compared with manual work, the stirrups can save 1% of materials and reduce the stirrups.The construction cost is increased because the main reinforcement is evenly distributed around its circumference and there are many reinforcing cages.It is very convenient to overlap and saves hoisting time.

Campany information

Tianjin Hongxing International Trade Limited Is A Member Of Hongxing Group .

It is mainly responsible for the exporting of steel products and equipment manchines. The company has professional sales team members who engaged in exporting business over 20 years.It has cooperated with buyers from more than 50 countries. The company is located in Tianjin city of China, a beautiful coastal city, where has Xingang port, one of the largest port in northern China. Relying on the convenience of transportation and the advantages of industrial resources, our company has established good cooperative relations with purchasers from all over the world. The mainly markets are including Southeast Asia, Middle East,South America, Africa, Europe,ETC.

The mother company Hongxing group has established a number of branch offices bases in Tangshan, Beijing, Shandong,Shanghai,Ningbo,Guangzhou and Hongkong,leads to our stable and good cooperation with local factories. Various products can be supplied, including steel wire ,rebar ,steel pipe , etc.In addition, there are rolling welding machines, forklift trucks, roof tile machine and other equipment products. and all of them are of good quality. We are looking for the global market sale network for many years and that is also our goals.

FAQ

Q:Where is the place of origin?

A:Our origin is China. We are a supplier of steel and machinery.

2. Q:What are the modes of shipment?

A:We usually use sea transportation or combined sea-land transportation according to customer's requirements.

3. Q: Minimum Order Quantity ?

A:Generally, it is a container with one equipment and 25 tons of steel.

4. Q: Do you provide samples? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost

of freight and the simple.

5 . Q:Can we visit your factory ?

A:Warmly welcome once we have your schedule we will pick you up .

It mainly controls from the aspects of feed inspection, production process, factory inspection and after-sales service to ensure the overall quality of the products.Incoming Inspection (IQC): Full inspection, random inspection and batch inspection of all incoming raw materials and spare parts. Distinguish the defective products that do not meet the company's requirements and make obvious indic...more