-

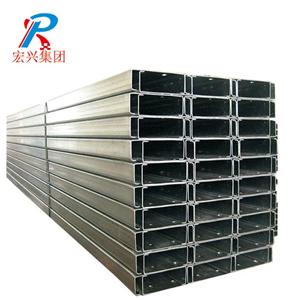

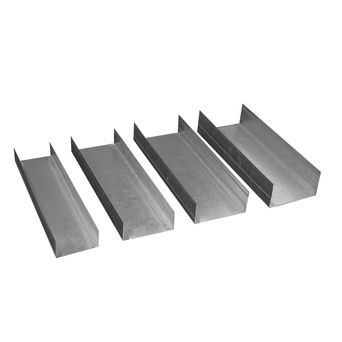

Galvanized Furring Channel

Keel is a kind of building material used to support modelling and fixing structure. It is widely used in hotels and terminal buildings. Passenger station, station, theatre, shopping mall, factory, office building, old building renovation, indoor decoration, roof and other places. Keel is the skeleton and base material of decoration, which is widely used. There are many kinds of keel, which can be divided into wood keel, light steel keel, aluminium alloy keel, steel keel and so on

-

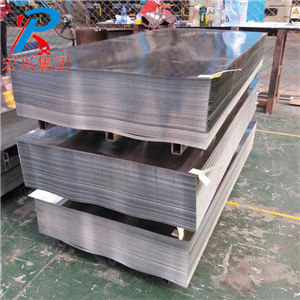

Galvanized Steel Flat

Flat steel refers to steel with a width of 12-300 mm, a thickness of 3-60 mm, a rectangular section and a slightly blunt edge. Flat steel can be used as finished steel or as blank for welded pipe and thin slab for laminated sheet rolling. Main Application: Flat steel can be used as finished material for hoop iron, tools and mechanical parts, and as building structural parts and escalators.

-

Black Steel Pipe

Welded steel pipes for low-pressure fluid transportation (GB/T3092-1993) are also known as general welded pipes, commonly known as black pipes. It is a welded steel pipe used for conveying water, gas, air, oil, heating steam and other general low pressure fluids and other purposes. The wall thickness of steel pipe can be divided into ordinary steel pipe and thickened steel pipe, and the nozzle end can be divided into non-threaded steel pipe (smooth pipe) and threaded steel pipe.

-

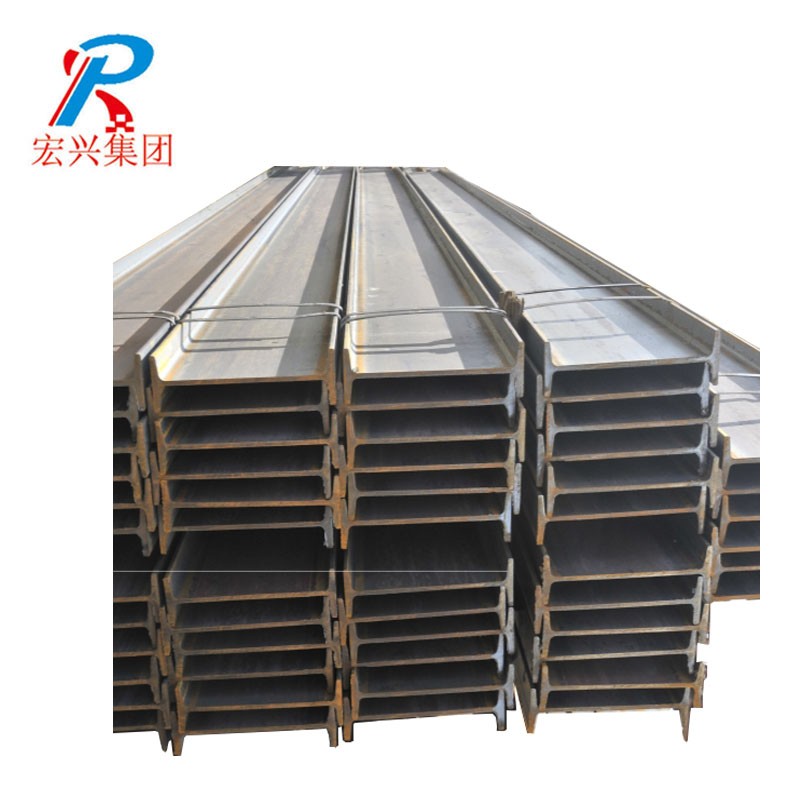

Steel I Beam

I-section steel, whether ordinary or light, has relatively high and narrow cross-section size, so the moment of inertia of the two main axes of the cross-section is quite different. Therefore, I-section steel can only be used directly for members bent in the web plane or for members subjected to lattice loads. Axial compression members or those that are perpendicular to the web plane and bending are not suitable for use, which limits their application. I-beam is widely used in construction or other metal structures.

-

Galvanized Steel I Beam

I-section steel, whether ordinary or light, has relatively high and narrow cross-section size, so the moment of inertia of the two main axes of the cross-section is quite different. Therefore, I-section steel can only be used directly for members bent in the web plane or for members subjected to lattice loads. Axial compression members or those that are perpendicular to the web plane and bending are not suitable for use, which limits their application. I-beam is widely used in construction or other metal structures.

-

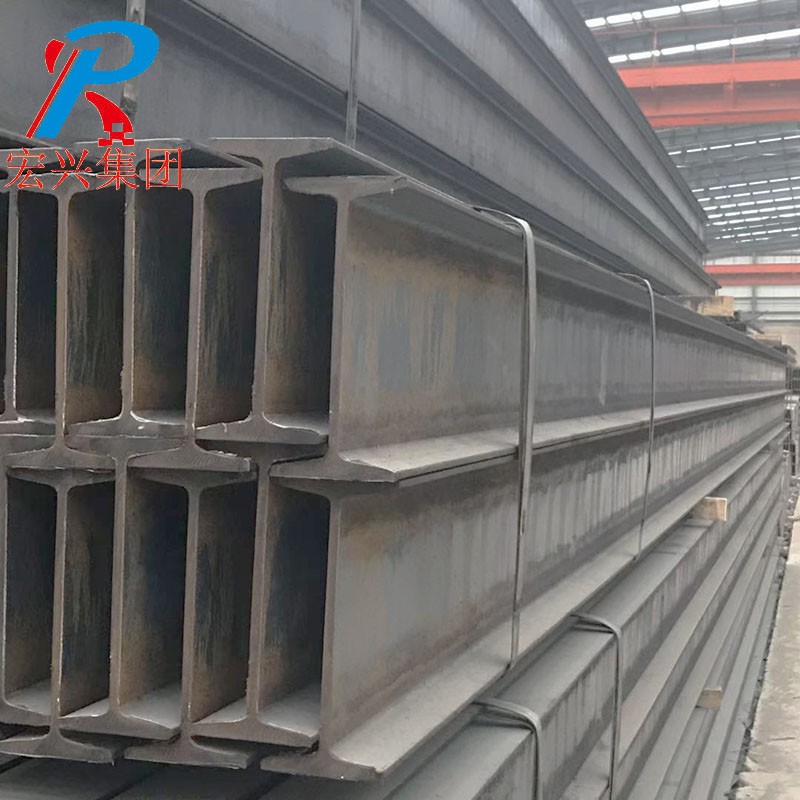

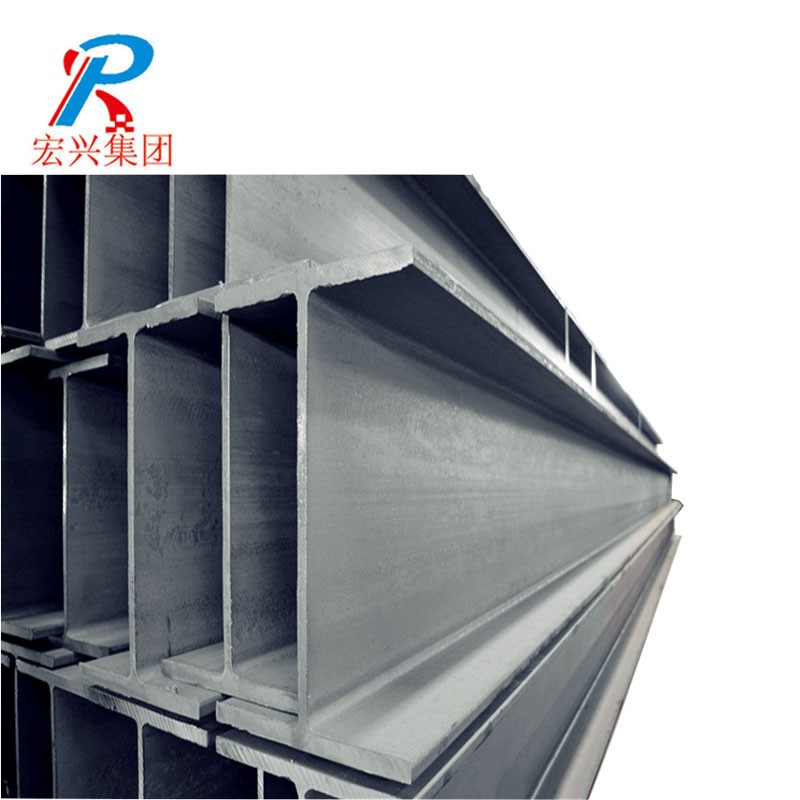

Steel H Beam

H-section steel is a kind of economic section high-efficiency profile with more optimized section area distribution and more reasonable strength-weight ratio. It is named because its section is the same as the English letter "H". Because H-beam is arranged at right angles in all parts, H-beam has the advantages of strong bending resistance, simple construction, cost saving and light weight in all directions, and has been widely used.

-

Galvanized Steel Wire

The surface of galvanized steel wire is smooth, smooth, without cracks, joints, prickles, scars and corrosion. The galvanized layer is uniform, strong adhesion, durable corrosion resistance, excellent toughness and elasticity. Tensile strength should be between 900 Mpa and 2200 Mpa (wire diameter 0.2 mm-4.4 mm). Torsion times (0.5 mm) are more than 20 times, and repeated bending should be more than 13 times. The thickness of galvanized layer is 250g/m. The corrosion resistance of steel wire is greatly improved.

-

Oval Steel Tubes

We offer a huge array of mild steel tube to use in different industrial application. We offer these premier quality Seamless Steel Pipes as per the diverse requirements of various industries. Taking into account the ever changing needs of our international clients, we offer these high grade Seamless Steel Pipes with unique features and higher efficiency. These seamless steel pipes are available in the following specifications:

-

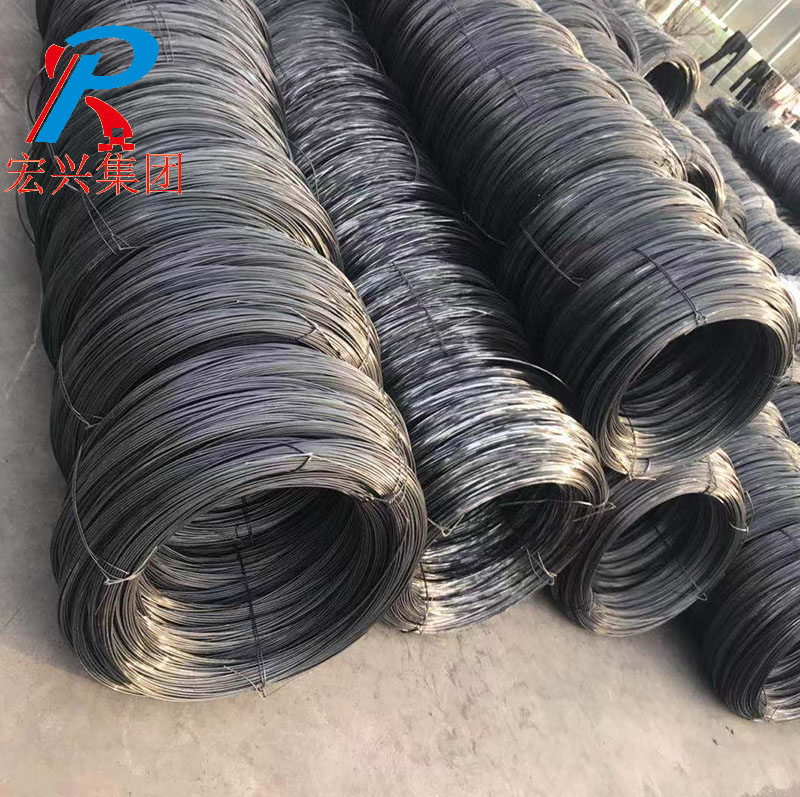

Annealed Steel Wire

Annealed wire is a kind of soft iron wire product made of low carbon steel by cold drawing, heating, constant temperature, heat preservation and other processes. The composition of iron wire varies according to its use. It contains iron, cobalt, nickel, copper, carbon, zinc and other elements. The hot metal billet is rolled into 6.5mm thick steel rod, that is, wire rod, and then put into the drawing device to draw into different diameter lines, and gradually reduce the diameter of the drawing disc, cooling, annealing, coating and other processing processes to produce various specifications of wire.

-

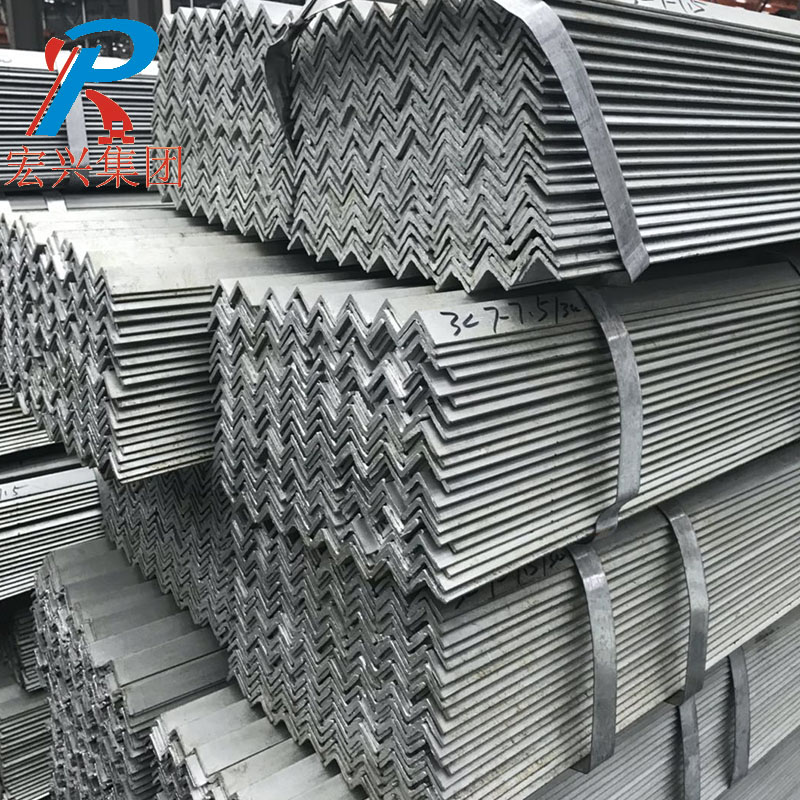

Steel Angle

Standard: AISI, ASTM, BS, DIN, GB, JIS Dimensions: 10*10mm-200*200mm Grade: Q195-Q420 Series Place of Origin: Hebei, China (Mainland) Brand Name: Tang Steel Model Number: Q235/Q345/SS400/S235/S275 Type: Equal Application: Engineering Structure Product name: Hot Rolled Steel Angle Bar Technique: Hot Rolled Angle Bar Surface treatment: Hot Dip Galvanised Shape: Equilateral Angle Bar Keywords: Angel Steel Bar Material: Q235/Q345/SS400/ST37-2/ST52/Q420/Q460/S235JR/S275JR/S355JR Length: 6m-12m

-

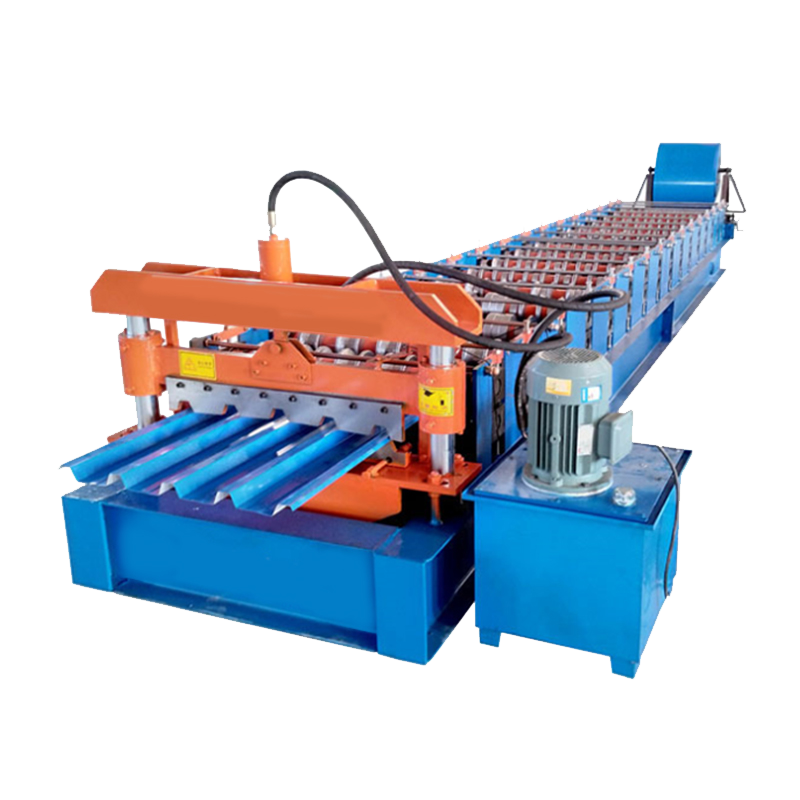

Roof panel roll forming machines

Two levels wave and trapezoid tile roll forming machine with cutting systerm is operated by a computer. It is easy to operate and can be set up in many languages to meet the needs of customers in many countries and regions. Two levels wave and trapezoid tile roll forming machine with cutting systerm is made up of laying out, forming and post-forming cutting. Its color plate has smooth and beautiful appearance, uniform paint pattern, high strength and durability. It is widely used in industrial and civil buildings, such as factory buildings, warehouses, gymnasiums, exhibition halls, cinemas and other rooms and walls. Two levels wave and trapezoid tile roll forming machine with cutting systerm using high quality steel products, complete product types and models.The technical performance index has reached the advanced level at home and abroad. Two levels wave and trapezoid tile roll forming machine with cutting systerm Special design and facture can be carried out according to user's requirements, and at the same time adapt to market changes, constantly upgrade and update.

-

concrete mixer machine

1. This concrete mixer machine is Smooth operation, low noise and no disturbance to the people. 2. This concrete mixer machine is Good mixing quality, high production efficiency and low energy consumption. 3. This concrete mixer machine is High degree of automation and simple operation. 4.This concrete mixer machine is Simple structure, easy to move and low maintenance cost. It is suitable for general construction sites, roads, bridges, hydropower and other projects, and is especially suitable for construction in urban residential areas.

- Home >

- Products

Products

Get the latest price? We'll respond as soon as possible(within 12 hours)