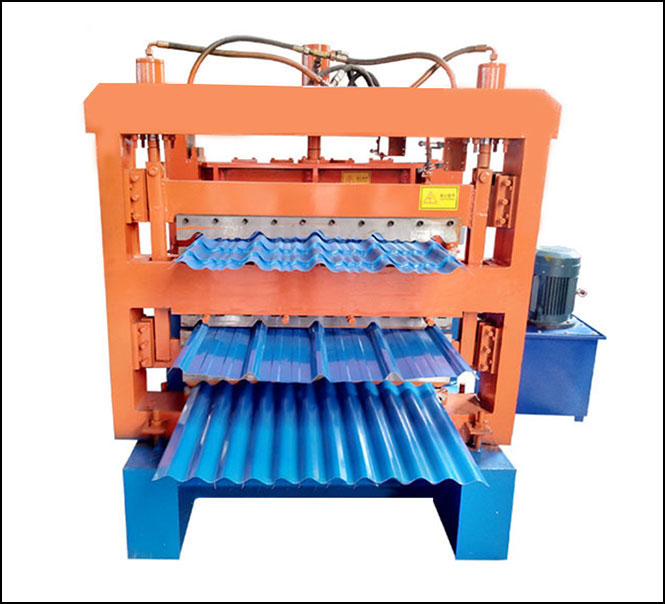

Roof panel roll forming machines

Brand :HONGXING

Product origin :made in china

Delivery time :30 days after receipt of deposit or L/C

Supply capacity :10 sets per month

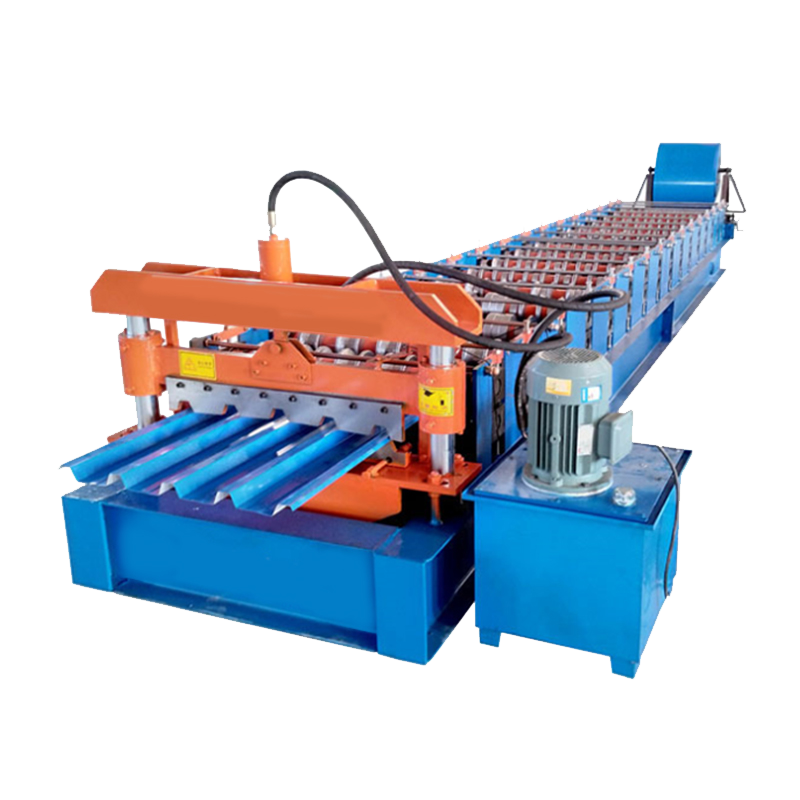

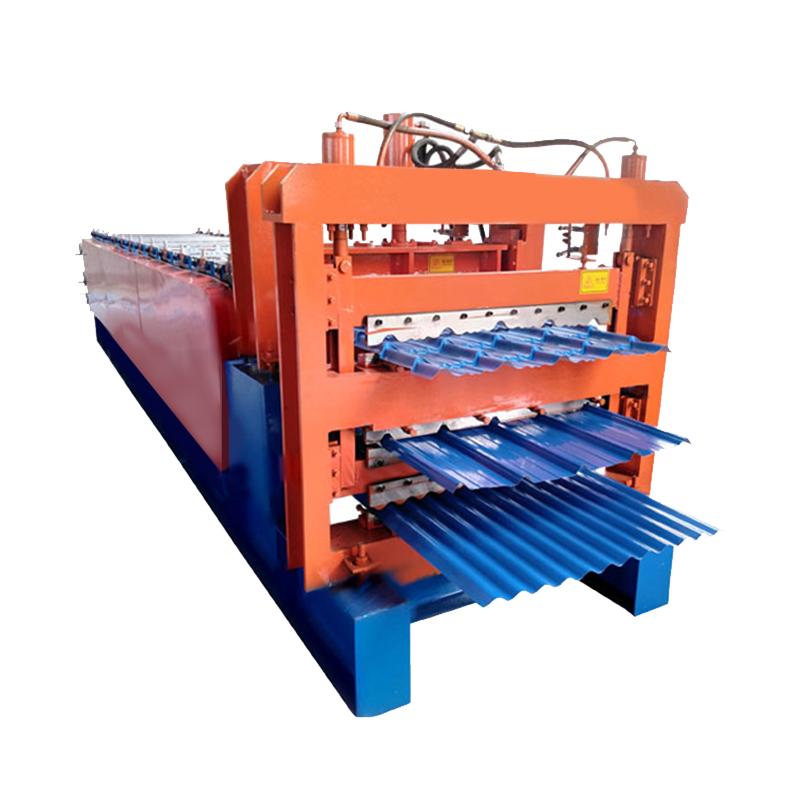

Two levels wave and trapezoid tile roll forming machine with cutting systerm is operated by a computer. It is easy to operate and can be set up in many languages to meet the needs of customers in many countries and regions.

Two levels wave and trapezoid tile roll forming machine with cutting systerm is made up of laying out, forming and post-forming cutting. Its color plate has smooth and beautiful appearance, uniform paint pattern, high strength and durability. It is widely used in industrial and civil buildings, such as factory buildings, warehouses, gymnasiums, exhibition halls, cinemas and other rooms and walls. Two levels wave and trapezoid tile roll forming machine with cutting systerm using high quality steel products, complete product types and models.The technical performance index has reached the advanced level at home and abroad. Two levels wave and trapezoid tile roll forming machine with cutting systerm Special design and facture can be carried out according to user's requirements, and at the same time adapt to market changes, constantly upgrade and update.

The tile roll forming machine(roofing tile corrugation forming machine),

Here are different model roll forming machines for your reference, and we can customize the roll forming machine exactlly according to your profile drawing.

Packaging and shipping

Lead Time:15 day(s) after payment received

Payment term: T/T or L/C

Trade Term : FOB CIF CFR or other terms

Place of Origin: China

Transport: Container or bulk vessel

Package : Standard export sea-worthy packing

Loading port: any port of china

Product parameters | |

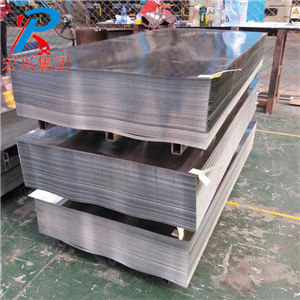

Suitable material | PPGI/Aluminium sheet/galvanized sheet/various sheet plates |

Thickness of coil sheet | 0.3-0.8mm |

Coil width | 1000-1200-1250mm |

Effective width | 784-980mm |

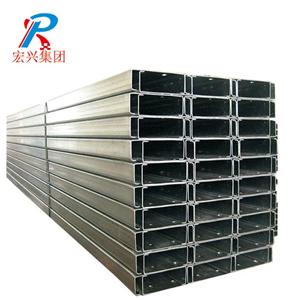

Material of main frame | 400H steel |

Diameter of Soild shaft | 70mm, high grade 45# steel |

Roller | High grade 45# steel, quenched and tempered treatment, hard chrome plated 0.05-0.07mm |

Thickness of middle plate | 16mm, 45# steel plate |

Forming roller station | 16 rows |

Drive type | By chain(1.0 inch), link bearing model 6210 |

Power of main motor | 5.5 kw, servo motor |

Sidewall connection bar | 25mm, zinc plated |

Forming speed | About 12-18m/min |

Hydraulic pump station | 5.5kw, 40# hydraulic oil |

Material of razor blades | Cr 12, quenching 58-62°C |

Frequency converter | It has the advantage of slowing down before cutting, to ensure the length accuracy ±1mm, far better than industrial standard ±3mm. |

Switch | CHNT |

Frequency changer | SAJ |

It mainly controls from the aspects of feed inspection, production process, factory inspection and after-sales service to ensure the overall quality of the products.Incoming Inspection (IQC): Full inspection, random inspection and batch inspection of all incoming raw materials and spare parts. Distinguish the defective products that do not meet the company's requirements and make obvious indic...more