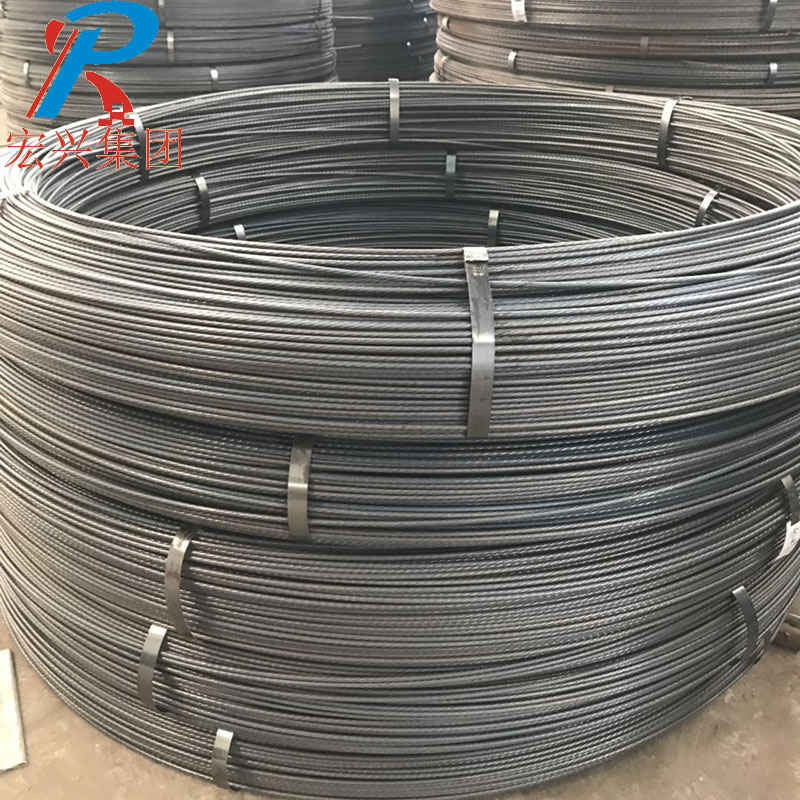

PC Steel Bar In Coil With Screw Type Thread On Surface

Brand :HONG XING

Product origin :Tangshan city, CHINA

Delivery time :Within 30 days

Supply capacity :5000MT per Month

PC Steel Bar In Coil With Screw Type Thread On Surface

Prestressed steel bar is the compressive stress exerted on concrete members by pre-tensioning method or post-tensioning method before the use of structural members. In reinforced concrete structures, members will crack when they are tensioned. Although it does not affect safety, it does not feel good. In this method, the steel bar is first tensioned and then poured into concrete. When the strength reaches the requirement, the steel bar will be loosened, and the steel bar will shrink. The method of pre-tensioning and post-tensioning is to pour the reserved holes in the concrete, then add the tensioned steel bar after forming, and then anchor the two ends of the component with instruments.

Applied to High-strength and stress tubular pile, pole,elevated bridge pier.ect

PC Steel Bar In Coil With Screw Type Thread On Surface

Application: Construction

Payment term: T/T or L/C

Trade Term : FOB CIF CFR or other terms

Place of Origin: China

Transport: Container or bulk vessel

Package : Standard export sea-worthy packing

Loading port: any port of china

Packaging Details:

1.Baling strip, inner PVC film, outer damp-proof paper-plastic compound packing cloth, wooden pallet pedestal.

2. According to customer's requirements.

Standard:GB/T5223, ASTMA421, BS5896, JISG3536

Dia: 4.0mm, 4.8mm, 5.0mm, 6.0mm, 6.25mm, 7.0mm,8.0mm,9.0mm

Tensile Strength:1470Mpa-1860Mpa

Coil weight: 0.8-1.1tons

Our Packing:

-In Container.

-Packed in coil.( around 0.8-1.1MT/coil )

-Each coil is strapped by steel bands at 8 places, fully wrapped with anti-rust plastic & P.P woven sheet with pallet and strapped again by steel bands at 6 places.

Seller is responsible for damages of goods resulting from defect of packing and formation of rust:

The details of product:

Campany information

Tianjin Hongxing International Trade Limited Is A Member Of Hongxing Group .

It is mainly responsible for the exporting of steel products and equipment manchines. The company has professional sales team members who engaged in exporting business over 20 years.It has cooperated with buyers from more than 50 countries. The company is located in Tianjin city of China, a beautiful coastal city, where has Xingang port, one of the largest port in northern China. Relying on the convenience of transportation and the advantages of industrial resources, our company has established good cooperative relations with purchasers from all over the world. The mainly markets are including Southeast Asia, Middle East,South America, Africa, Europe,ETC.

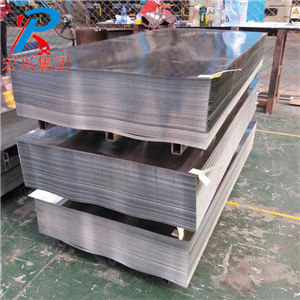

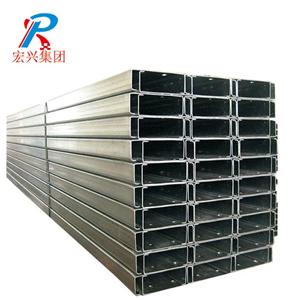

The mother company Hongxing group has established a number of branch offices bases in Tangshan, Beijing, Shandong,Shanghai,Ningbo,Guangzhou and Hongkong,leads to our stable and good cooperation with local factories. Various products can be supplied, including steel wire ,rebar ,steel pipe , etc.In addition, there are rolling welding machines, forklift trucks, roof tile machine and other equipment products. and all of them are of good quality. We are looking for the global market sale network for many years and that is also our goals.

FAQ

Q:Where is the place of origin?

A:Our origin is China. We are a supplier of steel and machinery.

2. Q:What are the modes of shipment?

A:We usually use sea transportation or combined sea-land transportation according to customer's requirements.

3. Q: Minimum Order Quantity ?

A:Generally, it is a container with one equipment and 25 tons of steel.

4. Q: Do you provide samples? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost

of freight and the simple.

5 . Q:Can we visit your factory ?

A:Warmly welcome once we have your schedule we will pick you up .

It mainly controls from the aspects of feed inspection, production process, factory inspection and after-sales service to ensure the overall quality of the products.Incoming Inspection (IQC): Full inspection, random inspection and batch inspection of all incoming raw materials and spare parts. Distinguish the defective products that do not meet the company's requirements and make obvious indic...more