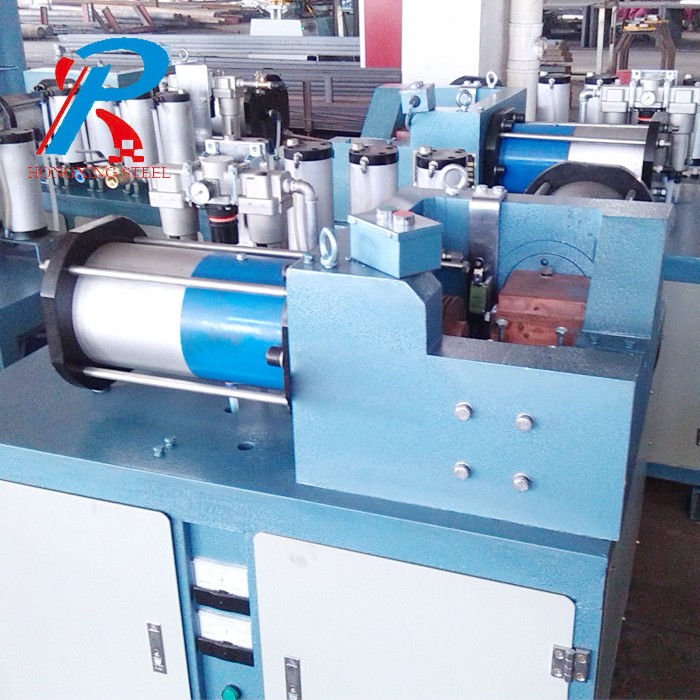

Automatic heading and cutter machine

Brand :HONGXING

Product origin :HeBei CHINA

Delivery time :15-30 days after receipt of deposit

Supply capacity :50 sets per mouth

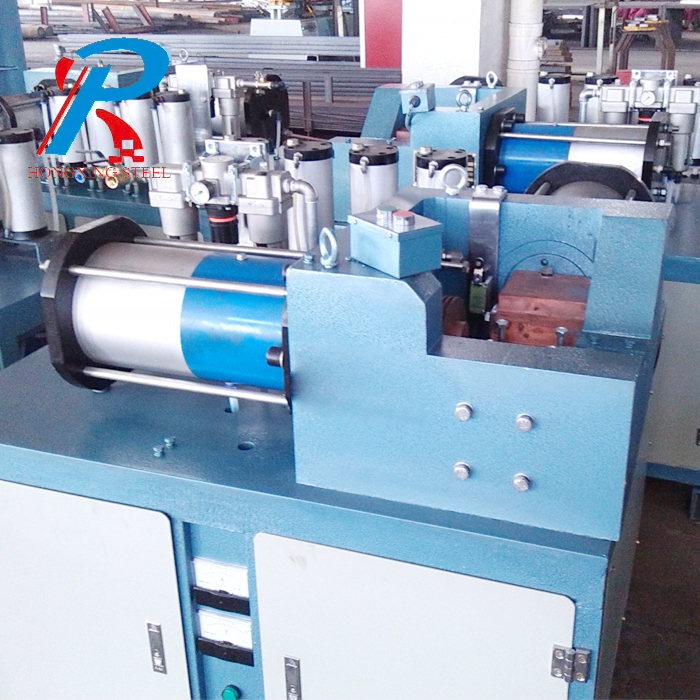

The auto bar moving machine matched with cutter and heading machine together,achieve to auto cutting,heading and moving bar away way .NC controller,mote adopts VFD,accurate speed,stably work,handle and Automatic way change any time,it can work in any where,easy installation,energy-efficient,after sale service with commercial cost.

The machine is easy to operate, with high-quality processing and high speed, free from the impact of the environment, which could upset 16-40mm HRB335 and HRB400 grade steel rebar.

Application and principle

The heading and cutting machine is simple in structure, light in weight, high in production efficiency, safe and convenient in use. Automatic cutting, laser alignment, remote control.

The pier head machine is mainly composed of upsetting frame, frame, transformer, hydraulic system and electrical system. Place the flat steel bar in the fixture of the upsetting machine, and the end is placed on the hammer of the upsetting machine. The upsetting cylinder and the clamping cylinder are fixed on the upsetting frame. Fixed fixture, movable fixture and movable upsetting hammer are installed together in the upsetting frame. The two ends of the secondary coil of the transformer of pier head machine are connected by copper band clamp and upsetting hammer respectively. Hydraulic system is mainly composed of motor, plunger pump, valve seat, electromagnetic reversing valve and cooler.

Warranty:1 Year

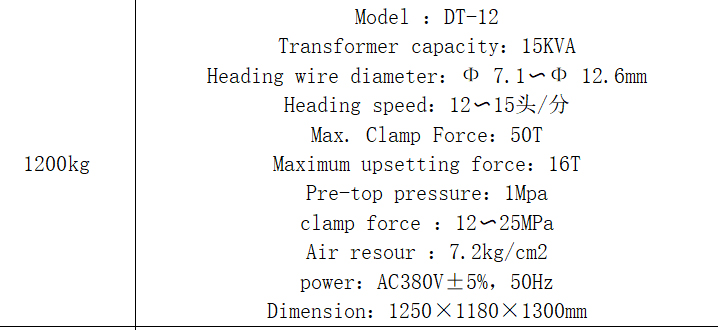

Product name:heading machine

Capacity:15KVA

Color:Customer's Requirement

Weight:1200kg

Length:10.4m-34.4m

Packaging Details:small parts in woodebox , electric parts covered by plastic ,

big machine in nude

Port:TianJin

Payment term: T/T or L/C

Trade Term : FOB CIF CFR or other terms

Campany infarmation

Tianjin Hongxing International Trade Limited Is A Member Of Hongxing Group .

It is mainly responsible for the exporting of steel products and equipment manchines. The company has professional sales team members who engaged in exporting business over 20 years.It has cooperated with buyers from more than 50 countries. The company is located in Tianjin city of China, a beautiful coastal city, where has Xingang port, one of the largest port in northern China. Relying on the convenience of transportation and the advantages of industrial resources, our company has established good cooperative relations with purchasers from all over the world. The mainly markets are including Southeast Asia, Middle East,South America, Africa, Europe,ETC.

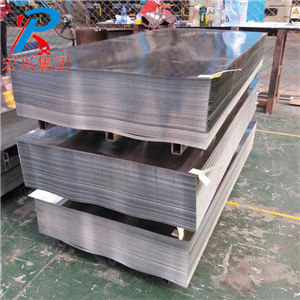

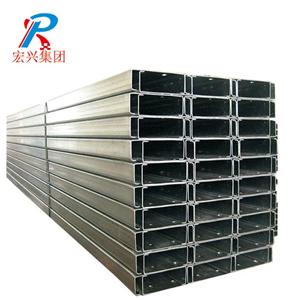

The mother company Hongxing group has established a number of branch offices bases in Tangshan, Beijing, Shandong,Shanghai,Ningbo,Guangzhou and Hongkong,leads to our stable and good cooperation with local factories. Various products can be supplied, including steel wire ,rebar ,steel pipe , etc.In addition, there are rolling welding machines, forklift trucks, roof tile machine and other equipment products. and all of them are of good quality. We are looking for the global market sale network for many years and that is also our goals.

FAQ

1. Q:Where is the place of origin?

A:Our origin is China. We are a supplier of steel and machinery.

2. Q:What are the modes of shipment?

A:We usually use sea transportation or combined sea-land transportation according to customer's requirements.

3. Q: Minimum Order Quantity ?

A:Generally, it is a container with one equipment and 25 tons of steel.

4. Q:How to quote?

A:Please offer the specification of the product ,such as material ,size ,shape, etc .So we can give the best offer.The quotation terms are generally CFR,CIF and FOB.

5 .Q: How to order?

A:Please send us your purchase order by email or fax. Or you can ask us to send you a proforma invoice for your order. We need to know the following information for your order.

It mainly controls from the aspects of feed inspection, production process, factory inspection and after-sales service to ensure the overall quality of the products.Incoming Inspection (IQC): Full inspection, random inspection and batch inspection of all incoming raw materials and spare parts. Distinguish the defective products that do not meet the company's requirements and make obvious indic...more