-

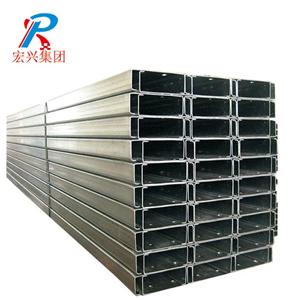

Prestressed Concrete PHC Pile Moulds

Product Name: Prestressed Concrete PHC Pile Moulds Concrete pile mould is position fixing is made by radial tongue-and groove and axial taper pin. Manufactured stage by stage and binded by bolts at last, the mould is characteristic with the advantages of esay transportation, quick assembling,correct position fixing, good rigidity and smooth working. We are professional manufacturer of Pre-stressed Concrete Pile Production Line. We have engaged in this area for many years and own mature technology, full experience. Our products are in accordance with the standard GB-13476-1999, the quality is guaranteed. Certification: ISO9001:2008 Running Wheel: 600-1800mm lengh: 7-60m Product: Concrete spun pile steel mould Shaping Mode: Die Casting

-

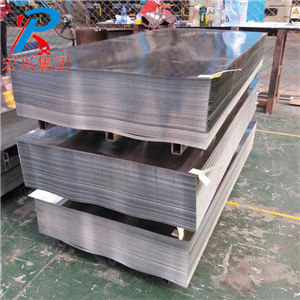

Making steel mould for PHC Pile Moulds

According to Concrete pile strength , there are PHC piles, and PC piles, According to different wall thickness, there are PC piles and PTC piles. Spun pile production line is used to produce High strength Cocrete piles. The popular specification of PHC piles are3 00mm ,400mm, 500mm, 600mm, 800mm and 1000mm, the length can be 7-15 meters, or we can design the mould according to your request. Main Features 1. We keep absorbing advantages of similar advanced products all over the world to keep our products alway going first . 2. The structure of this mould is novel, they are made in sections, and couple with bolts. 3. This spun pile mould is easy to transport and quick to assemble. Positioning is accurate. 4. It has good overall rigidity and smooth operation.

-

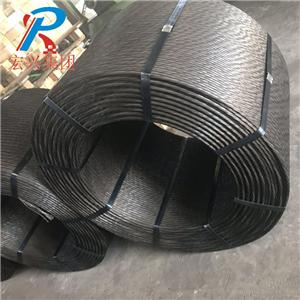

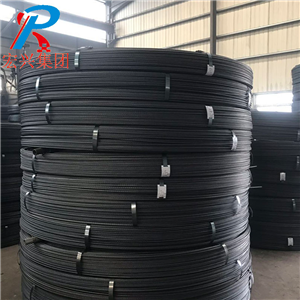

Steel PC Strand Wire

Steel PC Strand Wire Applied to High-strength and stress tubular pile, pole,elevated bridge pier.ect Steel Grade:77B/82B Wire Gauge:1-50MM Standard:AISI, ASTM, BS, DIN, GB, JIS Model Number: 1x7 Prestressed steel bar is the compressive stress exerted on concrete members by pre-tensioning method or post-tensioning method before the use of structural members. In reinforced concrete structures, members will crack when they are tensioned. Although it does not affect safety, it does not feel good. In this method, the steel bar is first tensioned and then poured into concrete. When the strength reaches the requirement, the steel bar will be loosened, and the steel bar will shrink. The method of pre-tensioning and post-tensioning is to pour the reserved holes in the concrete, then add the tensioned steel bar after forming, and then anchor the two ends of the component with instruments.

-

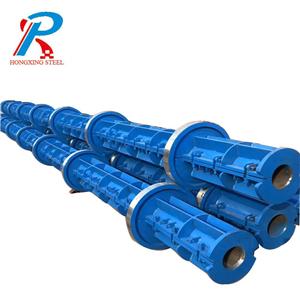

Tension machine for Electric Concrete poles

Prestressed tension is to pre-tension in the members, so that the pre-tensioned members are subjected to tensile stress, and then make them produce a certain deformation, to cope with the load of the steel structure itself, including the load of the roof weight, wind load, snow load, earthquake load and so on. Generally, steel strands, jacks, anchor plates, splints are used for tensioning.

-

Galvanized Steel PC Strand Wire

Product name:Strand wire Wire Gauge:12.7mm ,15.24mm Type:Copper Clad Steel Wire Special Use:Cold Heading Steel Usage:Construction Materilals Wire Gauge:12.7mm Structure:7 Wire Strand

prestressed concrete

Get the latest price? We'll respond as soon as possible(within 12 hours)