-

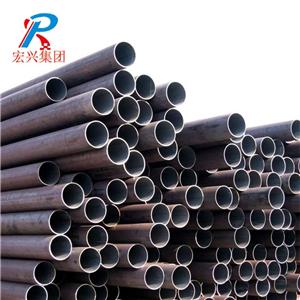

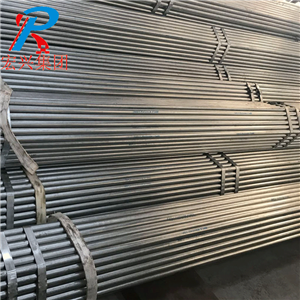

Black Steel Pipe

Welded steel pipes for low-pressure fluid transportation (GB/T3092-1993) are also known as general welded pipes, commonly known as black pipes. It is a welded steel pipe used for conveying water, gas, air, oil, heating steam and other general low pressure fluids and other purposes. The wall thickness of steel pipe can be divided into ordinary steel pipe and thickened steel pipe, and the nozzle end can be divided into non-threaded steel pipe (smooth pipe) and threaded steel pipe.

-

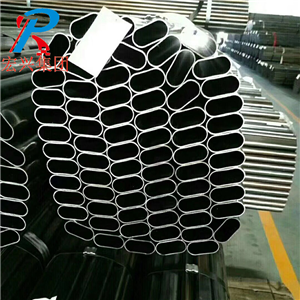

Oval Steel Tubes

We offer a huge array of mild steel tube to use in different industrial application. We offer these premier quality Seamless Steel Pipes as per the diverse requirements of various industries. Taking into account the ever changing needs of our international clients, we offer these high grade Seamless Steel Pipes with unique features and higher efficiency. These seamless steel pipes are available in the following specifications:

-

ERW Steel Pipes

ERW Steel Pipes is a kind of steel pipe which is formed by bending steel strip or steel plate into circular or square shape and then welded on the surface with joints. The blank used in welded steel pipe is steel plate or strip steel. Advantages and features Generally, ERW steel pipe has high accuracy, uniform wall thickness, high brightness of inner and outer surface of pipe (the brightness of steel pipe determined by the surface grade of steel plate), and can be arbitrarily ruled. Therefore, it embodies its economy and beauty in the application of high precision, medium and low pressure fluids. Welded steel pipe has the advantages of simple production process, high production efficiency, low cost and rapid development.

-

Radial extrusion cement pipe machine

Vertical radial extrusion pipe manufacturing technology as a new type of pipe manufacturing technology has the greatest advantage of using dry and hard concrete, vertical production can be immediately demoulded.Instantaneous extrusion molding, each tubeonly 2 to 4 minutes, high production efficiency. The radial extrusion pipe-making machine issuitable for producing small and medium-sized concrete drainage pipes. Its diameter range is300mm-1200mm. Its standard length is 2-3m. It can also produce reinforced concrete cement pipes with flexible joints and pipe jacking without reinforced concrete cement pipes.

-

Vertical Radial Extruder

Vertical radial extrusion pipe manufacturing technology as a new type of pipe manufacturing technology has the greatest advantage of using dry and hard concrete, vertical production can be immediately demoulded.Instantaneous extrusion molding, each tubeonly 2 to 4 minutes, high production efficiency. The radial extrusion pipe-making machine issuitable for producing small and medium-sized concrete drainage pipes. Its diameter range is300mm-1200mm. Its standard length is 2-3m. It can also produce reinforced concrete cement pipes with flexible joints and pipe jacking without reinforced concrete cement pipes.

-

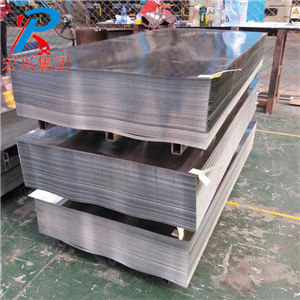

Galvanized Steel Strip

Galvanized strip is a long and narrow strip of cold-rolled or hot-rolled steel which is coated with a layer of raw material called zinc and aluminium in varying degrees. Hot-dip galvanizing has the advantages of uniform coating, strong adhesion and long service life. Complex physical and chemical reactions occur between hot-dip galvanized strip steel matrix and molten plating solution, forming a zinc-iron alloy layer with a close corrosion-resistant structure. The alloy layer is integrated with pure zinc layer and strip steel matrix. Therefore, it has strong corrosion resistance.

-

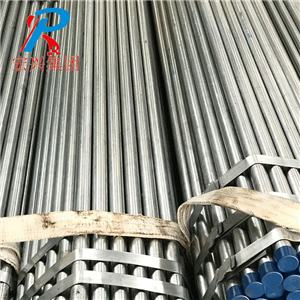

galvanized steel pipes

Welded steel pipe with hot dip or galvanized layer on the surface of galvanized steel pipe. Galvanizing can increase the corrosion resistance of steel pipe and prolong its service life. Galvanized pipes are widely used not only as pipelines for general low-pressure fluids such as water, gas and oil, but also for oil wells and pipelines in petroleum industry, especially in offshore oilfields, oil heaters, condensers and coolers for chemical coking equipment, pipes for coal distillate wash oil exchangers, and supports for Trestle pipe piles and mine tunnels. Wait a minute.

-

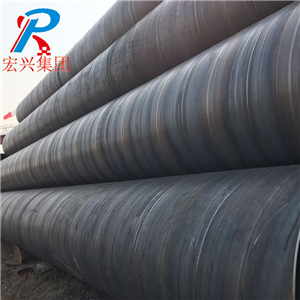

Round Steel Pipes

Spiral welded pipe is also a kind of welded pipe equipment. Its strength is generally higher than that of straight welded pipe. It can produce welded pipe with bigger diameter with narrower blank and welded pipe with different diameter with the same width blank. However, compared with the straight seam pipe of the same length, the length of the weld increases by 30-100%, and the production speed is lower. Therefore, most of the smaller diameter welded pipes are welded by straight seam welding, while the larger diameter welded pipes are mostly welded by spiral welding.Spiral steel pipe production process: The spiral seam steel pipe is made of strip coil plate as raw material, often extruded at high temperature, and welded by automatic double-wire double-sided submerged arc welding process.

-

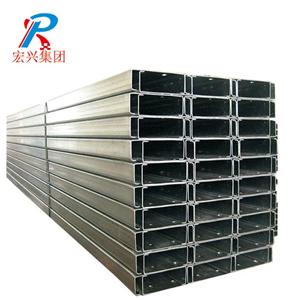

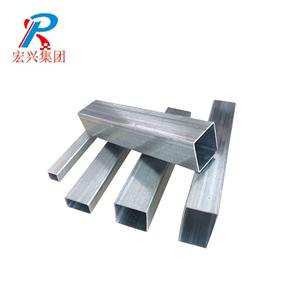

Square Steel Pipes

Square pipe, as its name implies, is a kind of square pipe. Many kinds of material can form square pipe. It is used for what purpose and where. Most square pipe is made of steel pipe. After unpacking, flattening, crimping and welding, it forms round pipe. Then it is rolled into square pipe and cut into needed pipe. Length. Generally, 50 square pipes per package are in large specifications at most 10*10*0.8-1.5-500*500*10-25 in spot. Square pipes are divided into structural square pipes, decorative square pipes, construction square pipes, mechanical square pipes and so on.

pipes

Get the latest price? We'll respond as soon as possible(within 12 hours)