-

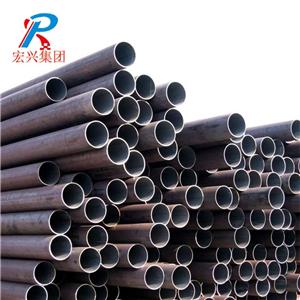

Black Steel Pipe

Welded steel pipes for low-pressure fluid transportation (GB/T3092-1993) are also known as general welded pipes, commonly known as black pipes. It is a welded steel pipe used for conveying water, gas, air, oil, heating steam and other general low pressure fluids and other purposes. The wall thickness of steel pipe can be divided into ordinary steel pipe and thickened steel pipe, and the nozzle end can be divided into non-threaded steel pipe (smooth pipe) and threaded steel pipe.

-

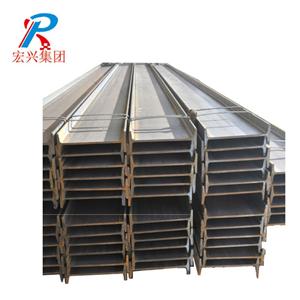

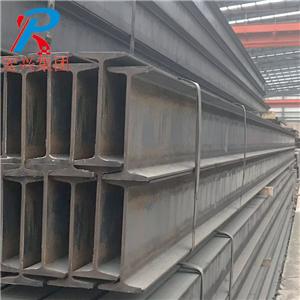

Steel I Beam

I-section steel, whether ordinary or light, has relatively high and narrow cross-section size, so the moment of inertia of the two main axes of the cross-section is quite different. Therefore, I-section steel can only be used directly for members bent in the web plane or for members subjected to lattice loads. Axial compression members or those that are perpendicular to the web plane and bending are not suitable for use, which limits their application. I-beam is widely used in construction or other metal structures.

-

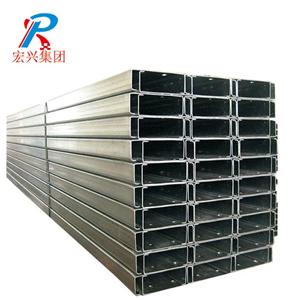

Galvanized Steel I Beam

I-section steel, whether ordinary or light, has relatively high and narrow cross-section size, so the moment of inertia of the two main axes of the cross-section is quite different. Therefore, I-section steel can only be used directly for members bent in the web plane or for members subjected to lattice loads. Axial compression members or those that are perpendicular to the web plane and bending are not suitable for use, which limits their application. I-beam is widely used in construction or other metal structures.

-

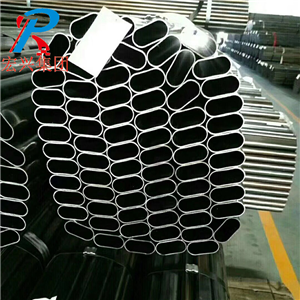

Oval Steel Tubes

We offer a huge array of mild steel tube to use in different industrial application. We offer these premier quality Seamless Steel Pipes as per the diverse requirements of various industries. Taking into account the ever changing needs of our international clients, we offer these high grade Seamless Steel Pipes with unique features and higher efficiency. These seamless steel pipes are available in the following specifications:

-

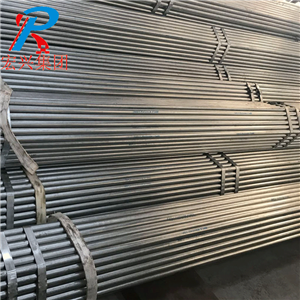

ERW Steel Pipes

ERW Steel Pipes is a kind of steel pipe which is formed by bending steel strip or steel plate into circular or square shape and then welded on the surface with joints. The blank used in welded steel pipe is steel plate or strip steel. Advantages and features Generally, ERW steel pipe has high accuracy, uniform wall thickness, high brightness of inner and outer surface of pipe (the brightness of steel pipe determined by the surface grade of steel plate), and can be arbitrarily ruled. Therefore, it embodies its economy and beauty in the application of high precision, medium and low pressure fluids. Welded steel pipe has the advantages of simple production process, high production efficiency, low cost and rapid development.

-

vertical concrete pipe making machine

Vertical radial extrusion pipe manufacturing technology as a new type of pipe manufacturing technology has the greatest advantage of using dry and hard concrete, vertical production can be immediately demoulded.Instantaneous extrusion molding, each tubeonly 2 to 4 minutes, high production efficiency. The radial extrusion pipe-making machine issuitable for producing small and medium-sized concrete drainage pipes. Its diameter range is300mm-1200mm. Its standard length is 2-3m. It can also produce reinforced concrete cement pipes with flexible joints and pipe jacking without reinforced concrete cement pipes.

-

Radial extrusion cement pipe machine

Vertical radial extrusion pipe manufacturing technology as a new type of pipe manufacturing technology has the greatest advantage of using dry and hard concrete, vertical production can be immediately demoulded.Instantaneous extrusion molding, each tubeonly 2 to 4 minutes, high production efficiency. The radial extrusion pipe-making machine issuitable for producing small and medium-sized concrete drainage pipes. Its diameter range is300mm-1200mm. Its standard length is 2-3m. It can also produce reinforced concrete cement pipes with flexible joints and pipe jacking without reinforced concrete cement pipes.

-

cast iron pipe fitting

Pipe fitting is the general name of the parts and components that play the roles of connection, control, direction change, diversion, sealing and support in the pipeline system.Steel pipe fittings are all pressure fittings. According to different processing technology, it can be divided into four categories: butt welded pipe fittings (welded and non-welded), socket welded pipe fittings, threaded pipe fittings and flanged pipe fittings.

-

Pipe fitting of nodular cast iron

The essence of cast iron pipe fitting is ductile iron pipe fitting, because ductile iron pipe fittinghas the nature of iron, steel performance, so there is this term. Graphite exists in spherical shape in nodular cast iron pipes. Generally, the size of graphite is 6-7 grade. In quality, the nodularization grade of cast iron pipes is required to be controlled at 1-3 grade and the nodularization rate is more than 80%. Therefore, the mechanical properties of the material itself have been improved, which has the nature of iron and the properties of steel. After annealing, the nodular cast iron pipe has ferrite and pearlite in its metallographic structure. It has good mechanical properties, so it is also called cast iron pipe. Features: It has the nature of iron, the properties of steel, excellent anti-corrosion performance, good ductility, simple installation, and is mainly used for water supply and gas transmission in Municipal Industrial and mining enterprises.

-

Cast Iron Elbow Pipe fitting

Cast Iron Elbow Pipe fitting, also known as elbow repair device, elbow plug, is a kind of emergency repair and plug for elbow itself or elbow and pipe joint leakage. Elbow Half fitting is mainly 90 degree elbow Half fitting . Cast Iron Elbow Pipe fitting structure: Elbow Huff fitting adopts upper and lower structure, lined with sealed rubber, directly aligned to the elbow position, locking bolts can be used. The ends of the elbow are stuck in the pipe, and the leaky elbow is wrapped in it.

-

Socket pipe repair section

Socket pipe repair section is a device for rush repair of leakage at the socket of the connection between two pipes. Pipe repair sectionis a device for rush repair of parts other than sockets. The device is simple in structure and consists of only two bodies and two rubber pads. Cast iron pipe fitting is easy to install and only pairs of two bodies. The emergency repair of pipeline can be completed by tightening the nut at the leaking point. The device can save the time of water shutdown and reduce the cost of emergency repair.

-

Cast iron saddle clamp

Pipe clamp refers to a kind of pipe fittings commonly used in water heating installation, which is used to fix pipes and ground (note that the geothermal ground or the location of pipes on the ground can not be fixed by drilling holes). The loops do not go inside the gypsum line, and the pipes for leveling the ground should also be fixed.

ipe

Get the latest price? We'll respond as soon as possible(within 12 hours)